Why the peristaltic pump is an excellent alternative for the wine industry.

Pumping delicate or finicky wines, such as Pinot Noir, can be challenging for wineries. Especially when the technology utilized requires significant maintenance that consequently leads to higher operational costs. Of course their are other alternative solutions such as designing and building a vertical winery that utilizes gravity to transfer the goods; however, this alternative is neither cheap or easily feasible for the modest winery.

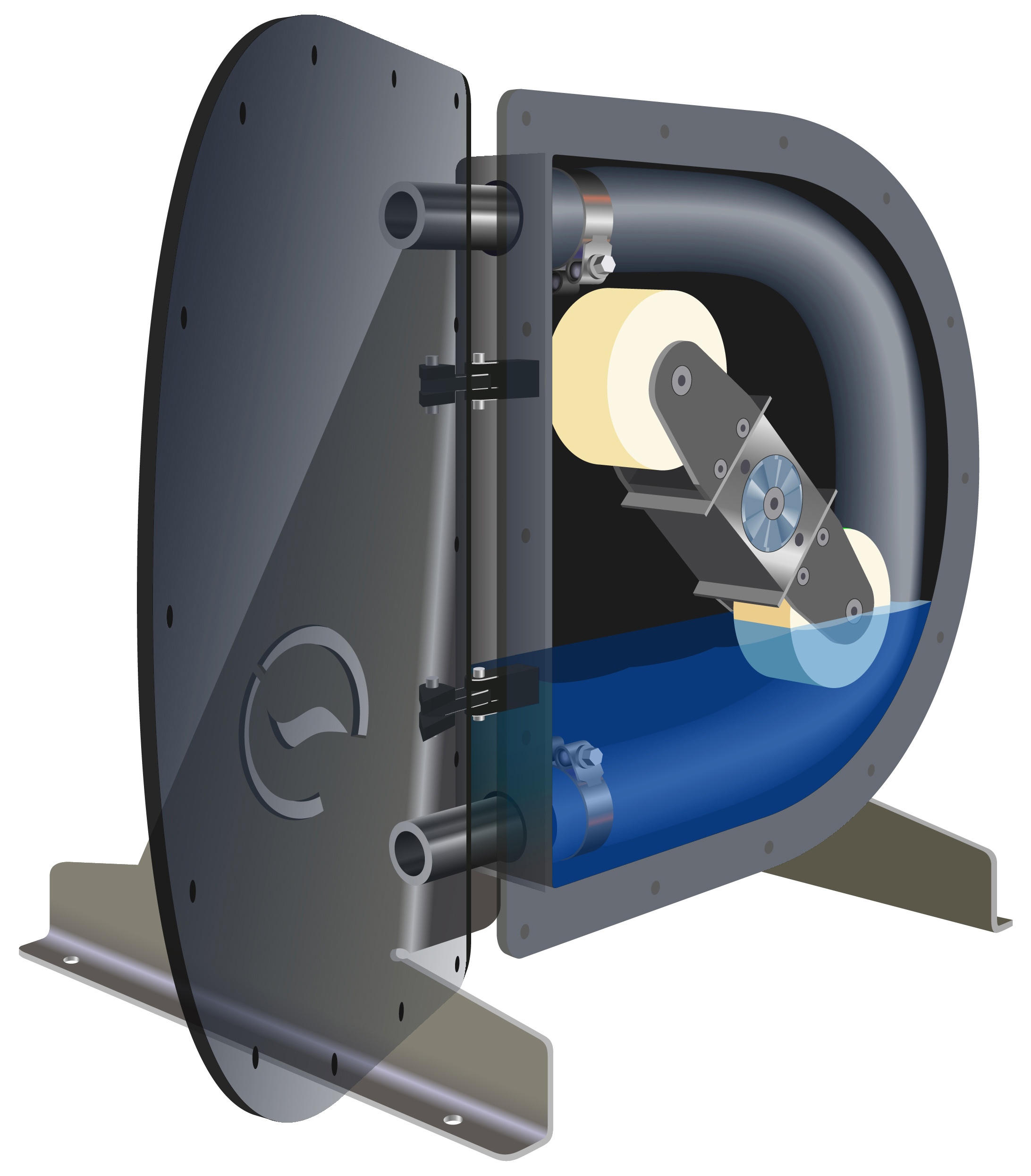

One technology that is overlooked in the U.S. wine industry for no apparent reason is the peristaltic pump. A peristaltic pump is a non-shear, low pressure positive displacement pump that works on the “squeeze-the-tube” principle.

Learn more about How a peristaltic pump works?

Outside the wine industry, the peristaltic pump is often utilized to transfer extremely fragile materials such as blood or viscous abrasive liquids and slurries that normally would damage other pump technologies. The peristaltic pump design is capable of pumping any liquid and most semi-solids that can fit in the inlet. Further, because this is a progressive cavity pump and the only contact the product sees is inside the hose or tubes the peristaltic pump does not shear the fluids or cavitate, so there is no air interchange or out-gassing. In the wine industry maintaining the integrity of the wine while transferring is essential.

According to Curtis Phillips, Wine Business Monthly “Within the wine industry, peristaltic pumps are marketed as being able to replace any other type of positive displacement pump (i.e., any progressive cavity, lobe or piston pump) in essentially any winery operation. Since the mechanical parts of the pump never touch the must/wine/lees, peristaltic pumps are resistant to abrasives like bentonite: an apparent advantage”

Zeroday’s Z ChemGear™ Peristaltic Hose and Tube Pump are highly reliable and easy to maintain. Changing out the tube or hose is effortless and requires minimal time. The new optimized design leads to a longer hose life due to the roller technology, and larger casing. Further with the right set up it can be a portable unit that can easily be moved around to the different wine processes:

|

|

These wine processes are listed in the order that typically occurs during the wine production. “If we look at things in terms of what is being pumped rather than focusing on winery operations, we see that we’re pumping grapes, juice, must, wine, pomace, marc, lees or Bentonite. We can lump these into a few categories: liquids (juice and wine), suspended solids in solution (grapes, must, lees and Bentonite), separated solutions (pomace and marc) and abrasive solutions (Bentonite).

Pretty much any winery pump design can move liquids like juice and wine while most can move solutions with suspended solids. The only limitations on the last category are the winery’s tolerance for any maceration of the suspended solids. Separated solutions require a positive displacement pump and generally need to have a pump that has been fitted with a hopper and feed auger. Abrasive solutions like Bentonite most likely will damage any pump except centrifugal and peristaltic pumps.” Curtis Phillips, Wine Business Monthly

Contact Zeroday today at 1-503-582-9067 to discuss your peristaltic pump needs.

Categories: Peristaltic Pumps