Coeur Silvertip’s Z ChemGear D300 Flocculant Mix-Feed System Delivered

Mainland Machinery fabricated, shipped and started up a Z ChemGear D300 dry flocculant mix-feed system for Coeur Mining’s Silvertip Mine which is located near the Yukon border west of Watson Lake. A 300 lb/day (140 kg/day) flocculant mixing-feed system is an over-under tank design concept developed by Zeroday Enterprises. This fully automatic system design features include:

- Entire system is a skid mounted integrated ‘plug-n-play’ setup for ease of startup, automatic running with feed pumps integrated in the control system.

- Over-under tank design where the mixing tank is located above the day tank with monitoring of both tanks. When day tank level reaches low-level limit an automated solenoid valve opens to gravity drain the mixed flocculant solution from the mix tank to day tank. After the mix tank is drained, the system automatically makes a new flocculant batch.

- Hopper capacity is 300 lb (140 kg) with an integrated bag breaker for easy filling. Flocculant feed rates are monitored and controlled to achieve an accurate concentration (±0.003% per batch at 0.25% concentration).

- The oversized lid reduces finger-pinching possibility.

- Dry polymer is fed from hopper into a wetting funnel that prewets the flocculant which flows into the suction of an eductor where complete flocculant particle dispersion is ensured before motive water carries the flocculant slurry into the mix tank.

- Tanks and hopper made from heavy-duty 10 GA 304 stainless steel passivated to minimize corrosion and increase tank life.

- Piping materials are either industrial duty PVC or stainless steel.

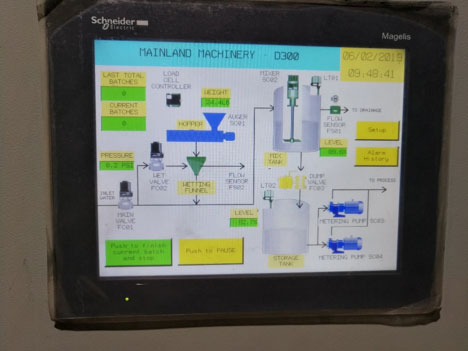

600V/3ph//60Hz NEMA 4 panel. - Control is by industrial standard PLC and 10.5” touch screen HMI using programmable logic to control the system.

- Control philosophy to protect the system from onsite low water supply pressure situation (i.e. no water at all) during auger running in order to ensure no flocculant is fed to wetting funnel without wetting and motive water.

- The system can be interrupted or paused due to emergency or maintenance service without losing system status information at shutdown so operation resumes at shutdown point.

- All operational parameters are adjustable on the HMI to optimize the system performance.

- A specifically sized AFX Mixer Technologies mixer ensures good, low shear mixing and flocculant dissolution.

- Three progressive cavity pumps provided with skid system, two operating with one standby, VFD controlled.

The Zeroday-Mainland Machinery partnership supplies effective and optimum mixing-feeding system designs for a range of different chemicals including flocculants, CMC, guar, xanthates, sodium sulfide (Na2S), sodium metabisulfite (MBS – Na2S2O5), metal salts (CuSO4, ZnSO4) and others. These are rigorously designed to be robust and for long life as well as built to maximize health and safety as well as environmental conditions meeting code requirements.

Mainland has engineering offices and fabrication shops in Abbottsford, BC Canada. Zeroday Enterprises is headquartered in Wilsonville, OR USA.

Silvertip D300 system in final assembly at Mainland Machinery.

Z ChemGear system HMI screen.

Z ChemGear D300 being Silvertip mill installation.